Agostoni is one of very few companies in the world that guarantees the control of the entire production process. Agostoni follows the best manufacturing practices and adheres to strict regulatory standards including BRC Global Food Safety Standards.

Processing

Chocolate that is produced responsibly from bean to bar

Cocoa Bean Testing

Sample testing: 4-stage test on beans. For organic and specific origins, testing a sample collected from every bag in every container.

Cocoa Liquor Testing

17-factor, 5-person flavor panel test run 2 times (on rough-grind lab liquor and again in tank samples).

New Product Development Mini Plant

Small industrial trials are made in internal pilot plant to ensure the scale-up production and consistently obtain the desired flavor profile.

Dedicated Bean Warehousing

Separate building + advanced pneumatic systems to ensure gentle handling (no broken beans) and zero dirt contamination in Cocoa Processing Hall.

Cocoa Bean Processing (Production of Liquor, Powder and Butter)

- 2 stage sterilization (Steam and then Infra-red)

- Air pressure controlled winnowing = no shell debris

- Roasting cocoa nibs for best development of flavors

- Liquor – 3-stage milling for exact control (down to 10-15 microns, depending on recipe)

- Liquor production – 3 stage milling and refining for the production of fine cocoa liquor (dwo to 15 micron, depending on the recipe)

- Steam deodorizer: new equipment that allow ICAM the development of

tailor made and mild flavor on cocoa liquor. - 3 presses for cocoa powder and butter production

Cocoa Powder Secondary Processing

Atmosphere protected, continuous tempering flow for outstanding color control, shelf stability

Mixing, Refining and Conching

Dedicated lines separate dark from milk & white and precise control of parameters on timing, micron fineness, etc.

Inclusion Quality Control

Total quality review of organic inclusions. Manual per-case inspection, testing, sieving and repacking. In-house metal detection system for secondary quality control.

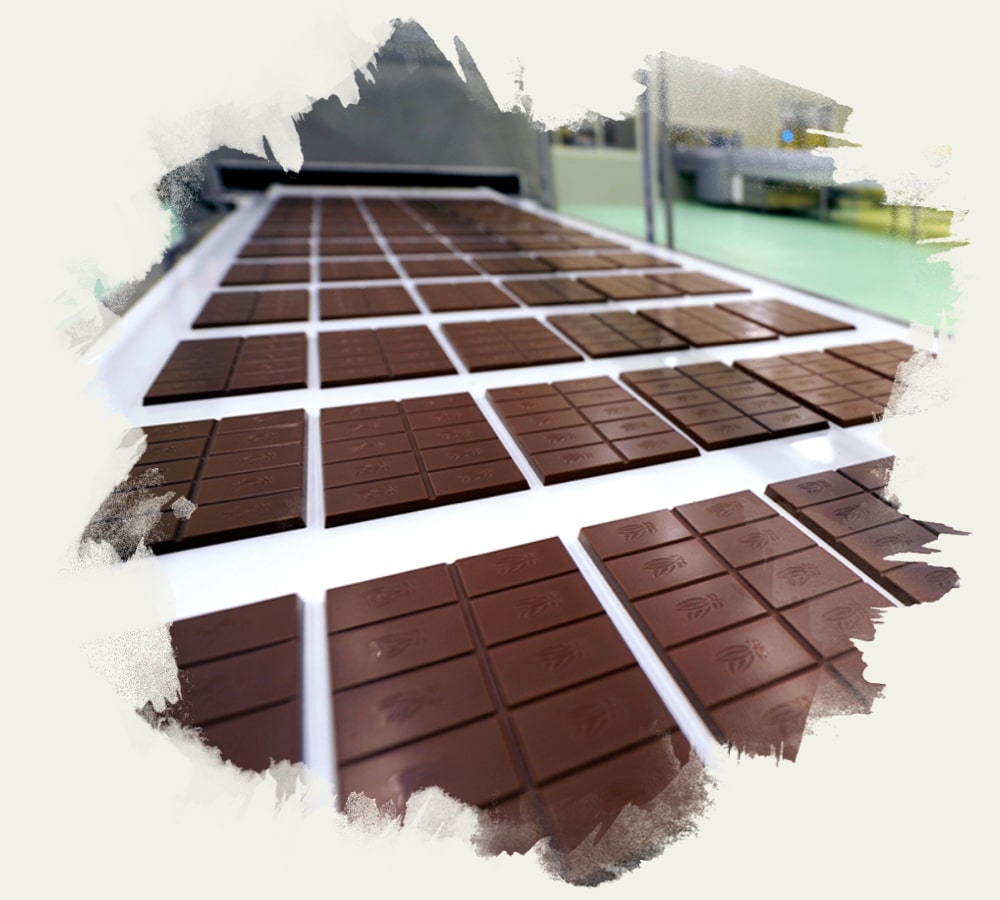

Molding Lines

Four moulding lines dedicated to tablets, pralines and filled items productions. Dedicated lines for dark couverture, chips and chunks production (possibility of milk free certifcation) and milk/white couverture, chips and chunks.

Packaging Lines

Flow wrap, thermo-seal, premium bars cartons, gift box, multi-bar packing, etc

Our certifications

The guarantee of excellence

We are sure to always operate ethically and attentively, so we strive for our commitment to be certified by external bodies as a further guarantee for the consumer.